- Category

- Business

How Russia is Boosting Arms Production Using Technologies from Ukraine's Allies

Since the beginning of its invasion of Ukraine in 2014, Russia has been subject to significant sanctions aimed at weakening its military-industrial complex (MIC). Despite these measures, Russia’s MIC has reached its highest production capacity since the Soviet era, particularly in recent years—especially following the 2022 full-scale invasion of Ukraine. This would not have been possible without the technology of Ukraine's allies.

Arms production in Russia has surged to new levels since the Soviet era—fueled in part by smuggled Western technologies, despite years of sanctions aimed at crippling its military-industrial complex.

The production of Kh-101 missiles, one of which recently struck the "Okhmatdyt" children's hospital, killing children and medical staff, has increased eightfold since 2022, with Russia manufacturing 420 of these missiles in 2023 alone.

Other sectors, such as drone construction and ammunition production, experienced similar growth. Russia continues to wage war in Ukraine and poses a threat to other countries, a feat made possible largely due to the technologies provided by Ukraine’s allied nations.

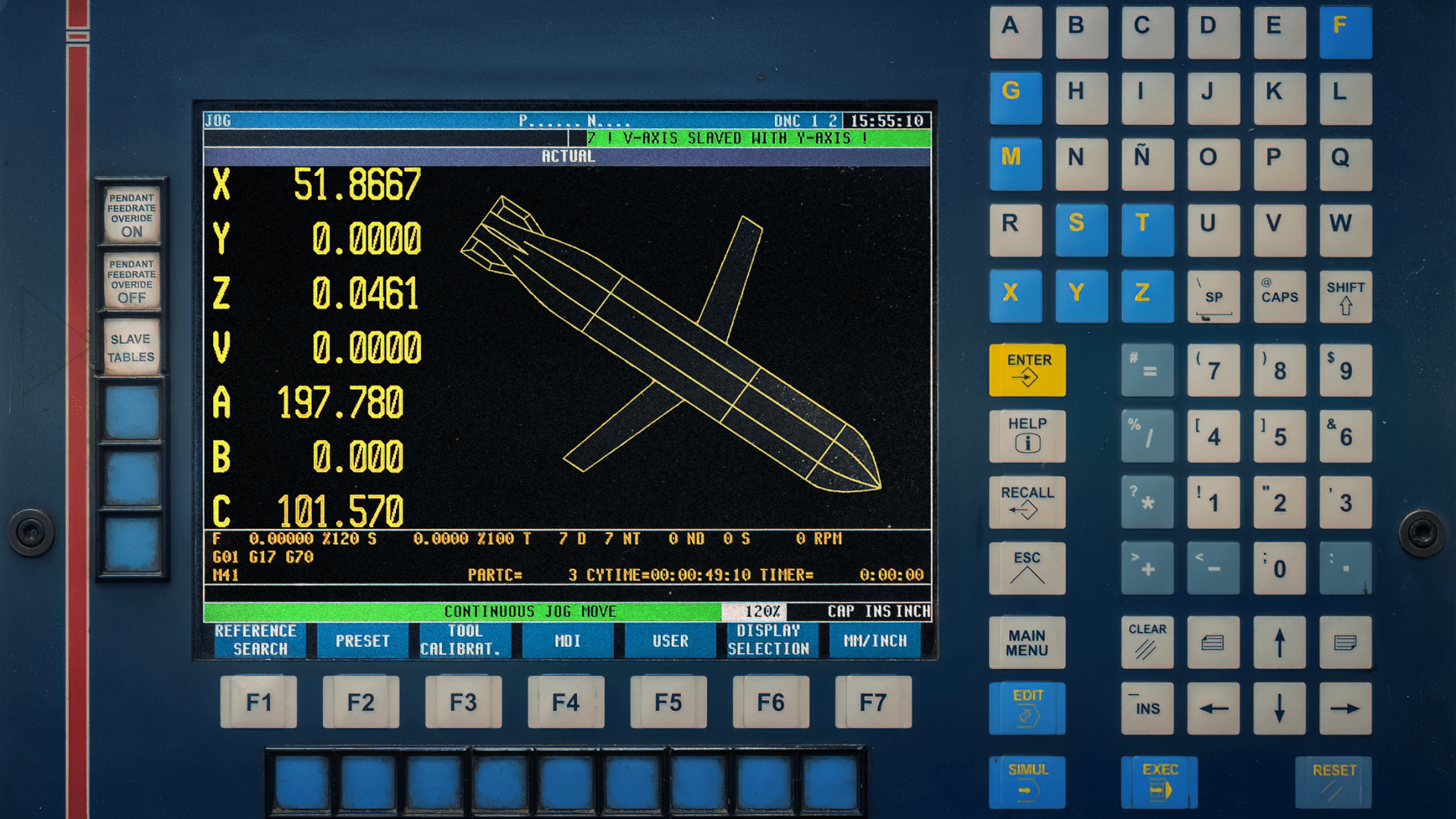

A key enabler of Russia’s current weapons manufacturing capabilities (especially missile production) is the use of CNC (Computer Numerical Control) machine tools. These advanced machines, mostly produced in Ukraine's allied countries, continue to strengthen Russia’s MIC.

Russian military-industrial complex critical technology

Modern defense manufacturing is critically dependent on technologies that Russia lacks domestically. Almost all missiles, aircraft, helicopters, tanks, ships, submarines, armored vehicles, and a significant portion of firearms, drones, and other military products in Russia today are produced using Western technologies.

CNC machines

CNC machine tools play a leading role in this production. They enable the rapid production of necessary high-precision components from metal and other hard materials, which are essential for manufacturing defense products.

"Of course, a CNC machine isn’t going to take a piece of steel and directly turn it into a complete missile casing or weapon system. But when it comes to different stages of the production process—like milling, grinding, cutting, laser processing, and electrical discharge machining—CNC machines are critically important," explains Agiya Zagrebelska, Head of the anti-corruption risk mitigation division in sanctions policy at the National Agency on Corruption Prevention (NACP).

Before the full-scale invasion, Russia sought to purchase such equipment mainly from Japan and the EU. After the invasion, trends shifted, and Russia focused on suppliers from Asia (China, Taiwan and South Korea). Despite this change, the majority of these machines are still equipped with CNC systems from German or Japanese manufacturers, who remain unrivaled in terms of quality.

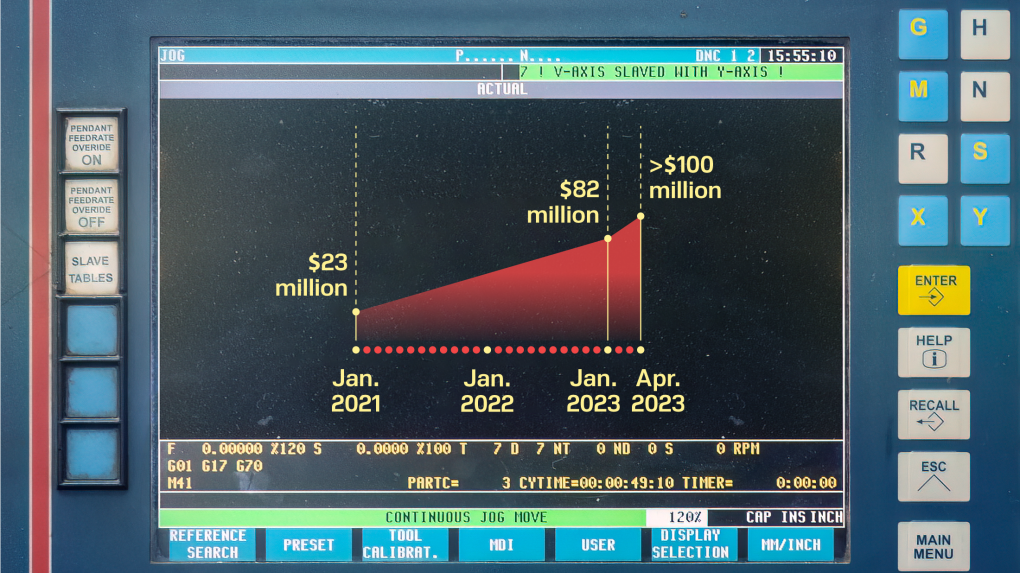

The import of such equipment has increased 3-4 times since Russia began its full-scale invasion. For example, in January 2021, Russia imported $23 million worth of such equipment; by January 2023, this figure had risen to $82 million. Despite international restrictions, Russia continued to ramp up imports, reaching over $100 million in monthly imports by April 2023, four times the amount imported before the full-scale invasion.

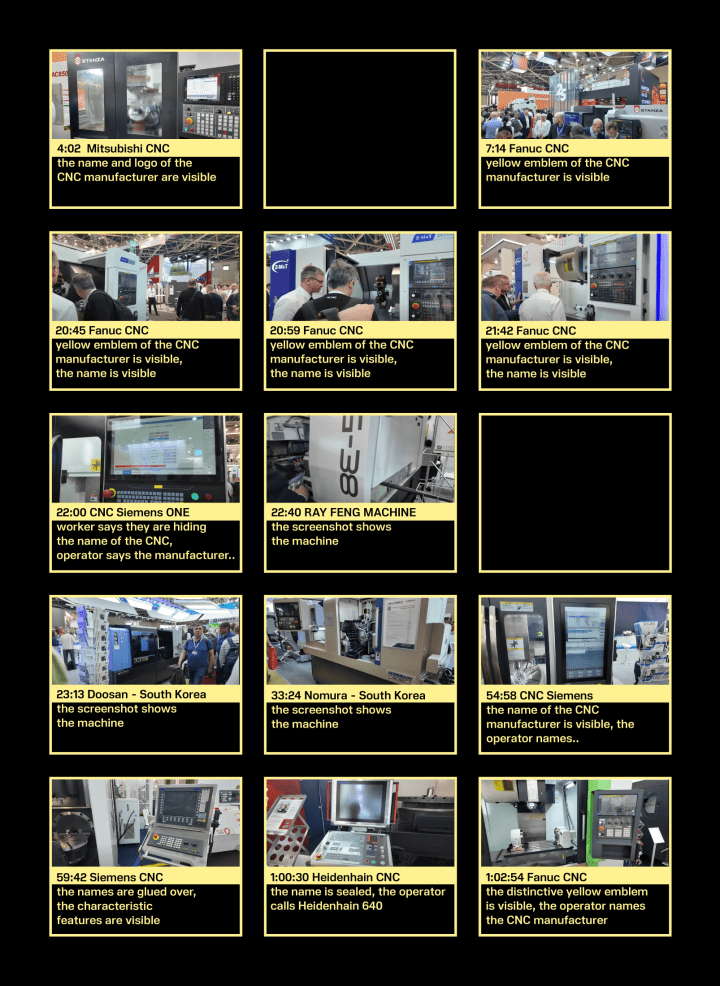

“Metalloobrabotka 2024” exhibition

While some of these machines may have been imported before the war, the technologies continue to be openly sold to Russia. A clear example of this trend is the “Metalloobrabotka 2024” exhibition held in Moscow this May.

On YouTube, you can easily find footage from this event. A video by the blogger "Operator CAD/CAM," with 19,000 subscribers, is titled "Metalloobrabotka 2024. Chinese Occupation. Mega Episode!!!”.

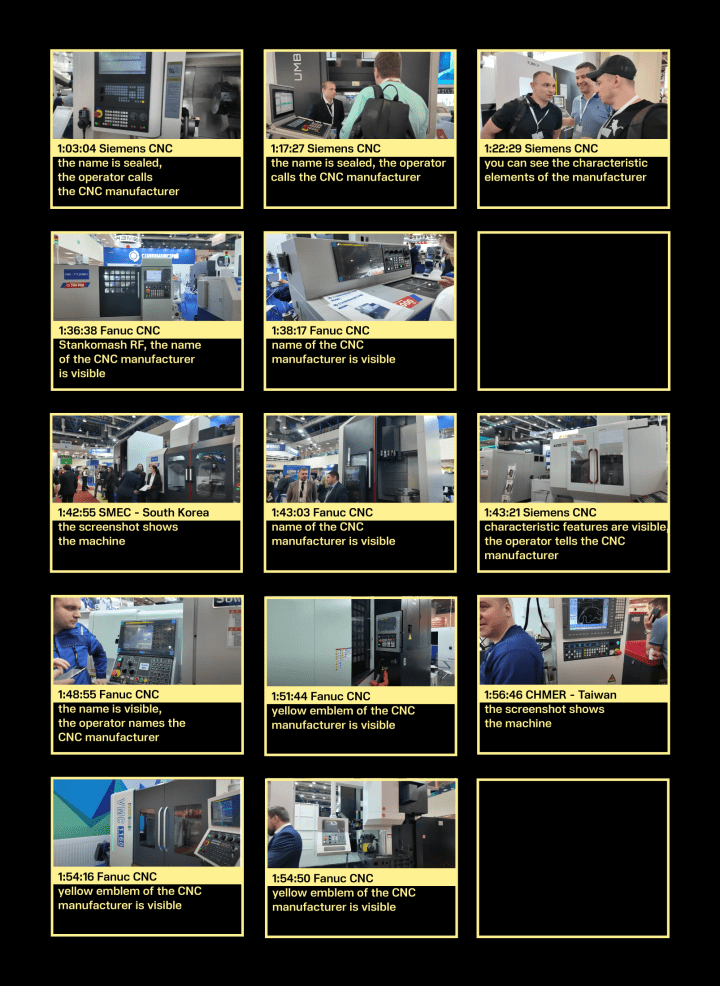

Even in this video, you can see 30 machines made mainly in China, but with CNC from Ukraine's allies. The technologies of these allies are present in almost every machine. Japanese CNC modules from Fanuc are openly displayed, while CNC systems from the well-known German companies Siemens and Heidenhain are hidden, but can be identified by other features visible in the video. At the same time, the exhibition includes samples of equipment from the Asian region, despite the ban on their sale to Russia.

Even though the exhibition doesn’t seem to be a militarized event, much of this equipment is likely to end up in defense enterprises. This is because the defense sector is the only rapidly growing part of Russia’s economy with the state resources to invest in production equipment upgrades.

"Russia’s defense industry is the primary user of such equipment,” explains Olena Yurchenko, a senior advisor and chief analyst at Ukraine’s Economic Security Council.

“Out of the 210 Russian machine tool importers analyzed, at least 190 have worked with or are still working with defense enterprises. The defense sector is the only client of this scale because Russia’s civilian production isn’t developed enough to need large amounts of expensive high-tech equipment. Efforts to boost Russia’s domestic machine tool production and replace imports have had limited success, often amounting to placing a Russian brand on lower-quality Chinese equipment."

The role of CNC machines in weapons production

Today, processing parts of various levels of complexity is nearly impossible without CNC metalworking machines, and the proportion of such operations in weapons production is quite high.

"These machines are used in producing components for nearly all modern weapons, ranging from artillery barrels and shells to rocket engine turbines and even nuclear weapons. The main difference is in the equipment specifications, especially when it comes to precision," explains Yurchenko.

The Soviet defense industry relied heavily on manual machine tools, which made the sector extremely dependent on skilled personnel. Most of these skilled workers were lost during the 1990s when defense sector factories in Russia were idle due to the economic crisis. Today's technologies compensate for this loss.

"The use of CNC machines speeds up production, ensuring that components are more precise, higher quality, and longer-lasting, standardizing the production of existing weapon models, investing in new developments, scaling and expanding production, and reducing personnel—one CNC machine operator can replace 15 traditional machinists," says Zagrebelska.

We found similar equipment at most plants involved in missile and other weapons production.

Examples of Russian defense plants using CNC technology

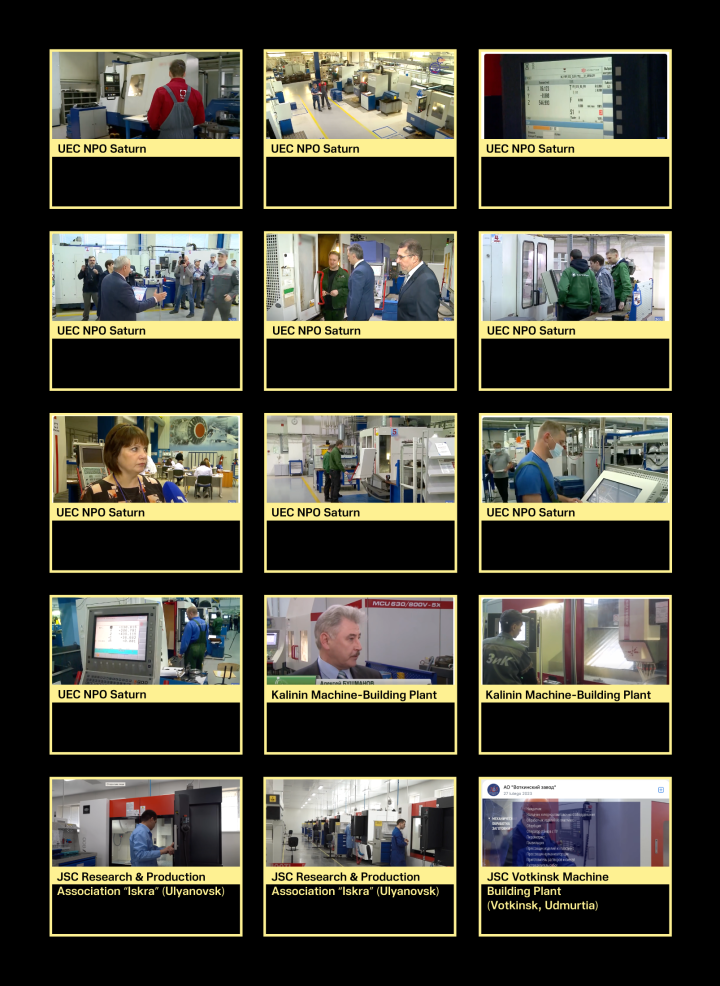

UEC NPO Saturn

UEC NPO Saturn manufactures engines for cruise missiles. These engines are used to power Kh101 missiles, one of which recently hit the Ohmadet children's hospital and killed doctors and children undergoing treatment there.

In the various videos we analyzed, we can see machines from the following manufacturers: Hermle, MAS Kovosvit and CNC Heidenhain (Germany), CNC-Interservice Zlín, Soustruh SPR 63, CNC Sinumerik 828 (Siemens, Germany).

Kalinin Machine-Building Plant

S-300 missiles are manufactured in Kalinin Machine-Building Plant, the main purpose of which is air defense, but after certain modifications, Russia began to fire them at Ukrainian cities. Due to their low accuracy, residential buildings and other civilian objects are most often targeted. This plant also produces missiles for the Buk-M1 complex. Back in 2014, Russia shot down a civilian Boeing Malaysia Airlines plane from such a complex, killing hundreds of people. In the video, you can identify equipment similar to the MAS Kovosvit MCU 630/800V-5x machine and Heidenhain (Germany) CNC.

Research & Production Association “Iskra”

JSC Research & Production Association “Iskra” manufactures engines for the Typhoon and Bulava missiles. The latter is an intercontinental ballistic missile capable of carrying a nuclear payload. Russia has been blackmailing the world with nuclear threats from time to time. You can find the equipment here: MAS Kovosvit CNC MCU 800V, CNC Siemens Sinumerik 840D sl.

Votkinsk Machine Building Plant

The Iskander missile system is manufactured at JSC Votkinsk Machine Building Plant. These hypersonic missiles are regularly used by the Russian Federation to shell Ukrainian cities. Since their flight time is very long, civilians do not have time to react to the air raid and take cover. Sometimes Russia deliberately hits precise targets with such missiles; at the beginning of the invasion, Russia hit the Mykolaiv Regional State Administration and killed about 50 of its employees. In the video from the enterprise, the TOS Varnsdorf machine and the Siemens Sinumerik 828 CNC are identified.

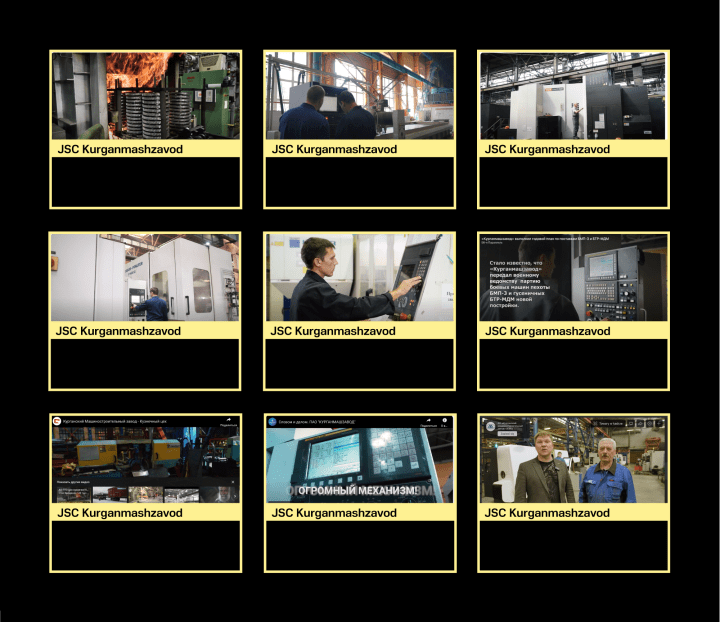

Kurganmashzavod

JSC Kurganmashzavod produces almost all the main armored infantry vehicles used in the war against Ukraine. These include BMP-3, BREM-L, BMD-4M, BTR-MDM and other vehicles. At the beginning of the invasion, the Russians used this armored vehicles to commit a large number of war crimes against the civilian population. The following equipment can be identified here: Mazak FH 10800, Gleason-Pfauter p400 "Gleason-Pfauter Maschinenfabrik GmbH, Trumpf SE + Co. KG Germany, KAFO HMC-800, grinding machineDanobat S. Coop. DMG-MORI, Fanuc 01-MF Fanuc Japan, Omax Waterjet.

Overall, we managed to find video footage from 95 Russian defense plants and identified 270 CNC machines originating from Ukraine's allied countries.

Why is Russia still receiving Western technologies and what can be done?

Today, direct supplies of such equipment are prohibited, but Russia is doing everything it can to acquire them. The latest trend involves exporting machine tools from China with CNC systems from countries allied with Ukraine.

Russia’s surge in arms production underscores how effective its sanctions evasion tactics have become. To circumvent sanctions, Russia employs networked supply chains through intermediary companies in various countries (China, Turkiye, UAE, Serbia, Kyrgyzstan, Kazakhstan, and others). While Western partners are attempting to impose sanctions on these intermediaries, the sheer number of them overwhelms current sanctions procedures. New mechanisms are urgently needed, such as the US Presidential Executive Order of December 2023, which targets financial institutions facilitating transactions that bolster Russia’s military power.

Blocking Western tech from reaching Russia

A comprehensive approach involving multiple government agencies of foreign partners is necessary today, along with a shift in how sanctions are perceived — they must be recognized as a critical weapon in the hybrid war that Russia initiated long before 2022.

"The issue of continued supplies despite sanctions (through third countries) lies in effectively enforcing the imposed restrictions and punishing violations," says Zagrebelska.

She also proposes a set of measures for the governments of countries whose equipment continues to reach Russia, as well as for the manufacturers involved:

Approve and publish a list of equipment (tools, spare parts, technical fluids, and software) subject to enhanced export control.

Prohibit the re-export of such equipment to Russia, Belarus, Iran, and North Korea.

Standardize enhanced inspection procedures for supplies to jurisdictions at risk of sanctions circumvention.

Require manufacturers and sellers of machines to include a clause prohibiting re-export to Russia, Iran, and North Korea, and extend such obligations to plants located in third countries.

Require manufacturers to install GPS trackers and remote control systems.

Require manufacturers to investigate cases of their equipment being supplied to Russia and publish the results of such investigations.

Extend restrictions to plants in third countries and production facilities that use trademarks and/or operate under license.

Extend restrictions and regulations to the used equipment market.

Increase liability for sanctions violations, including negligence that led to such violations (without intent).

Ensure greater involvement of banks through transaction checks (similar to combating money laundering and terrorism financing, AML/CFT).

Introduce a whistle-blowing mechanism to obtain insider information on violations.

Share information and coordinate efforts with other countries.

CNC machines are not like electronic components that can be found on marketplaces.They belong to a specialized market that can and should be tightly controlled through stricter export regulations. Doing so would significantly weaken Russian war industry and potentially save tens of thousands of lives, all without causing substantial economic losses for Ukraine’s allies.

-206008aed5f329e86c52788e3e423f23.jpg)

-270e13af43760897c8cb3e7f3ee9adf1.png)

-b63fc610dd4af1b737643522d6baf184.jpg)

-099180a164f53abb1128c9b5025a2b0e.jpg)

-46f6afa2f66d31ff3df8ea1a8f5524ec.jpg)

-4390b3efd5ecfe59eeed3643ea284dd2.png)